Okokuqala, ii-multilayer co-extrusionI-resistance diaphragm iyifilimu yepulasitiki.Emkhakheni wemikhiqizo yepulasitiki, ngokuvamile sibhekisela emikhiqizweni yepulasitiki eyisicaba enogqinsi olungaphansi kuka-0.2 mm njengamafilimu epulasitiki, lawo anogqinsi oluphakathi kuka-0.2 no-0.7 mm njengamashidi epulasitiki nalawo anogqinsi olungaphezu kuka-0.7 mm njengamapuleti.I-Multilayer co-extrusion resistance diaphragm izoba nokusebenza okuthile kokuvimbela igesi.Isithiyo lapha sisho ikhono lokuvikela lemikhiqizo yepulasitiki (iziqukathi, amafilimu) ngokumelene namagesi amangqamuzana amancane kanye nephunga.Ngokuvamile sisebenzisa ukungena kwegesi ukukala ukungena kwemikhiqizo yepulasitiki.I-PE, PP kanye namanye amapulasitiki ajwayelekile anamanani amakhulu okungena kwegesi, okungukuthi, ukungena kwegesi kubi, kuyilapho i-PA, i-PVDC, i-EVOH nezinye izinto ze-resin zinamanani aphansi kakhulu okungena kwegesi kunamapulastiki ajwayelekile, futhi ukungena kwegesi kuhle.Ngakho-ke, sivame ukubiza i-ifilimu ye-multilayer coextrusionequkethe okungenani into eyodwa ye-resin ye-PA, PVDC ne-EVOH njenge-multilayer coextrusion resistance diaphragm.I-PE, i-PA, i-TIE, i-EVOH namanye ama-resin angasetshenziselwa ukupakisha i-vacuum yemikhiqizo yobisi, ujamu, imikhiqizo yenyama, njll.

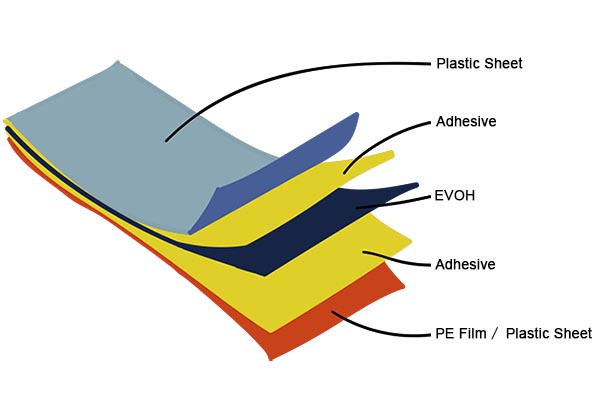

Amafilimu ama-multilayer akhishwe ngokubambisanaikakhulukazi yamukela ungqimba lwe-ABCBA5 uhlaka olulinganayo, olune-PA noma i-EVOH njengongqimba lwesithiyo kanye ne-polyethylene njengongqimba lophawu olushisayo.I-adhesive resin isetshenziselwa ukuhlukanisa ungqimba lwesithiyo olungaxhumekile kanye nongqimba lophawu olushisayo.I-PA noma i-EVOH izwela kakhulu kumswakama, ivikelwe ungqimba lwe-polyethylene, futhi ukusebenza kwayo okuhle kakhulu kwesithiyo somoya-mpilo sekuthuthukiswe ngokugcwele.Ngokuvamile, ukwakheka kweifilimu ye-multilayer co-extrudedkuya ngezidingo zokusebenza zefilimu.Ngokwesisekelo sokuhlangabezana nezidingo zenqubo, inhlanganisela yama-polymers ahlukene ingahlangabezana nezidingo zokusebenza zezinto zokupakisha ezifana nesithiyo, ukuvalwa kokushisa, amandla omzimba, ukubhoboza okushisayo, ukuguquguquka kwemvelo, izici zokucubungula okwesibili kanye nokwandiswa kwendawo yokugcina kanye nempilo yeshalofu.Ngokombono wezidingo zokusebenza, inhlanganisela yama-polymers amahlanu yanele.Nokho,ifilimu eyinhlanganisela ehlanganisiweezinezingqimba eziyisikhombisa, eziyisishiyagalolunye, eziyishumi nanye noma ngaphezulu zisetshenzisiwe emakethe okwenza kube yinjwayelo futhi kuthuthuke ngokushesha.Ukwakhiwa kwesakhiwo sefilimu ehlanganisiwe kuyadingeka kancane kancane ukuze kuzuzwe isimo esihle sokuhlanganisa umsebenzi, ubuchwepheshe, izindleko, ukuvikelwa kwemvelo, ukuphepha kanye nokucutshungulwa kwesibili.

1. Ukuqhathaniswa kwezindleko

Ukusebenzisa ama-polymer ashibhile ngaphezulu esikhundleni sama-polymer abizayo kunganciphisa izindleko zemikhiqizo futhi kunokusebenza kokuvala ukushisa kanye nokumelana nomswakama ophezulu wama-polymer e-ionic chain.Okwezinto ezisetshenziswayo ezinesithiyo esifanayo nekhono lokushisa-seal-ifilimu evuthelwe ungqimba oluyisi-7 i-co-extrusion iyonga kakhulu kunefilimu enezendlalelo ezi-5.

2. Umgoqo

Ukusebenzisa ama-polymer amabili ahlukene esikhundleni se-polymer eyodwa kungqimba lokuvimbela kungathuthukisa kakhulu impahla yayo yokuvimbela.Isibonelo, inhlanganisela yongqimba lwe-EVOH kanye nezinto ezivamile zenayiloni akukwazi nje ukugcina ukungena kwe-PA, kodwa futhi kwandise amandla e-EVOH futhi kuthuthukise ukumelana nokuqhekeka kwe-EVOH ngoba ungqimba lwe-EVOH lufakwe phakathi kwezingqimba ezimbili ze-PA amine, okwenza ifilimu enesithiyo esiphezulu, kuyilapho ifilimu ye-co-extrusion enezingqimba ezinhlanu ayikwazi ukufezwa.Izindleko ezikhuphukile zokwengeza i-EVOH zingangezwa ekusetshenzisweni okuphelele kwesakhiwo.Izinga lokudluliswa kwe-oksijini yefilimu enezingqimba ezinhlanu ekhishwe ngokuhlanganyela nesakhiwo se-PA esingu-20% singamayunithi angu-3.5, kodwa ngaphansi kwezimo ezifanayo, izinga lokudlulisela le-EVOH elingezwe kufilimu yezendlalelo eziyisikhombisa lingamayunithi angu-0.13.

3. Ukumelana nokuqhekeka

Izici ze-PA co-extruded films anezendlalelo ezengeziwe zingathuthukiswa.Isibonelo, ukusetshenziswa kwesendlalelo sokunamathisela esengeziwe kungathuthukisa ukusebenza kwesithiyo sefilimu ngokukhulisa umphumela wokuvimbela umhwamuko wamanzi wefilimu.Enye inzuzo etholakala ngesikhathi esifanayo ukuthi ingenza ifilimu ithambe kakhulu, ibe mnandi futhi ibe nokuphikiswa okuhle kokuqhekeka.

Ngokuqhubeka okuqhubekayo kobuchwepheshe be-polymer synthesis, ama-polymers amasha anezici ezihlukile zomzimba nezomshini angasetshenziswa kabanzi ukuhlangabezana nezidingo zokupakisha.Umsebenzi nesakhiwo seifilimu ye-multilayer co-extruded substrate eyinhlanganiselaizoba nokuguquguquka okukhulu nomnotho.Ngokusebenzisa kanye nokuthuthukiswa kwemishini yokubumba nobuchwepheshe, kuhlanganiswe nomklamo oyingqayizivele futhi ophumelelayo wesakhiwo esiyinhlanganisela, abakhiqizi bamafilimu bazoba nendima yenguquko ekuphishekeleni nasekucabangeni kwemodi yokucabanga yemibono yokuhlukahluka kwemisebenzi yokupakisha, ukulungiswa kwesakhiwo sokupakisha, kanye ukukhulisa izinzuzo zokupakisha.

Isikhathi sokuthumela: Apr-17-2023